Pick & Place Speed Increase

GOAL

Decrease pick and place cycle time without changing pick tooling

HIGH-PERFORMANCE SOLUTION

Constraints

-

Determine acceleration limits for picker tooling

-

Confirm constrained motions like pick direction and speed

Design

-

Develop motion profiles with continuous jerk

-

Blend X and Z motions of picker tool to allow accelerations to be lower in magnitude and longer in duration

Results

-

Cycle time reduced by 40% enabling higher throughput of machine

-

Peak picker tool accelerations reduced by 20% improving reliability

Precision Material Control

GOAL

Develop device to precisely control fabric edges during sewing

HIGH-PERFORMANCE SOLUTION

Constraints

-

Fabric speed during sewing operation

-

Device cannot damage thin knitted fabrics

Design

-

Maintain constant contact with fabric

-

Mitigate device to fabric slip through understanding force balance

-

Provide solution to regain control if slip occurs

Results

-

Device controls fabric edge to within +/- 2 mm at full speed

-

Device awarded patent

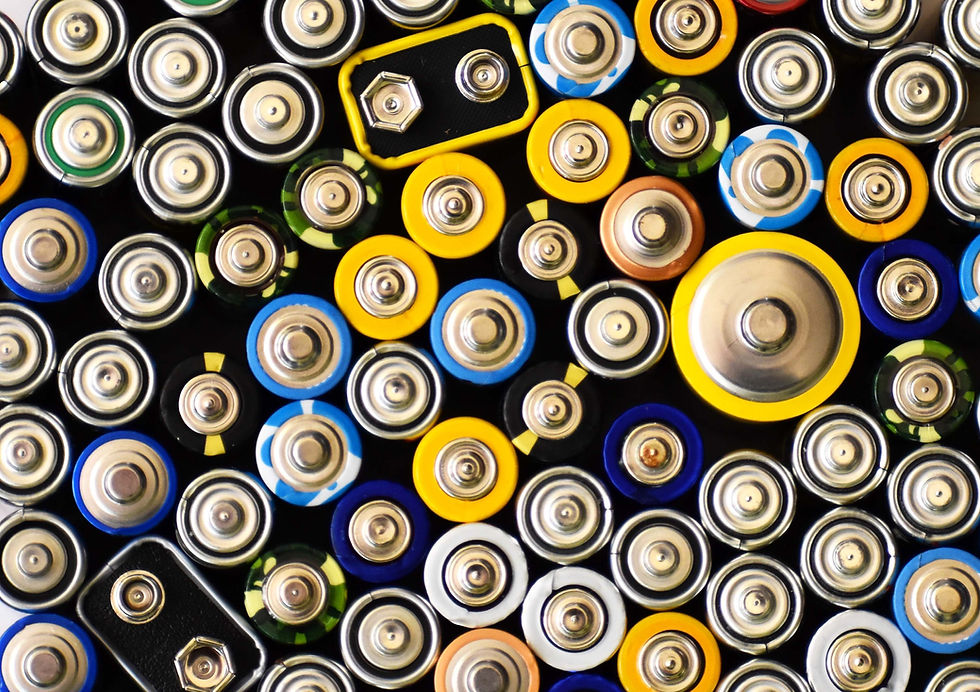

High Speed Cell Tester

GOAL

Double the throughput rate of previous testing equipment

HIGH-PERFORMANCE SOLUTION

Constraints

-

Maintain same footprint as previous equipment

-

Maintain same test procedure

Design

-

Develop multi-axis electromechanical cam drive system to synchronize test head to continuous feed belt

-

Optimize motion profile to minimize servo size and energy consumption

Results

-

First production tester achieved target rate with qualified test procedure upon factory acceptance testing